You’ve probably seen catalogs that

have inkjet decal paper advertised and thought “I wonder how difficult making my

own decals would be?” Well it’s really not that difficult, but up until now

it’s kind of been a ‘black-art’ meaning there hasn’t been too much press on the

subject. I want to tell you about my experiences with creating my own decals,

now I’m certainly no authority on making decals but I have learned a few things

along the way that hopefully will help people produce good results.

First I think a brief explanation of

how mass produced decals are made might be helpful in understanding the

limitations that come with making your own decals. Several companies make

‘water-slide’ decals; they typically are pad printed onto clear decal paper

stock. The inks used come in many colors including white and metallic colors

such as silver and gold. Because the inks are water based they need a sealant

to protect them. This typically is clear polyurethane which is applied over the

ink. They apply the sealant using a screen pad which only applies sealant to an

area slightly larger than the design, this saves money.

Unfortunately, making your own decals

using an inkjet printer has some limitations which you should be aware of.

First, the majority of inkjet printers will not print the color white. Those

that do are very expensive; printers use the white background of the

paper as white color in the design. Second, all but the most expensive printers

will not print metallic colors such as gold or silver.

I’ll discuss some other limitations

concerning sealing the decals later, right now let me show you how I got

started.

I purchased the

Testors Custom Decal System (704-9198) and an extra package of white decal

paper (704-9202). Read the instructions and install the software and your

almost on your way.

I’d like to tell you

a few more things to keep in mind before you print your first decal sheet. It’s

important to maximize the design space on each sheet, using 1 sheet to make a

small design isn’t a good use of your materials.

When you become prolific at making

decals, (and you will!) you’ll soon find yourself running out of supplies like

decal bonder spray and decal paper. I have never tried any other brand of decal

paper than Testors, so if anyone has, please feel free to comment.

There has been some talk on various forums

about using a gloss finish spray such as Testors or Floquil as a decal bonder,

all I can say about this is that I have tried them and they do not work. The spray left the surface of the decals

sticky even after soaking them in water. And when attempting to slide the

decals on to the surface they stuck to anything that touched the face of the

decal, (fingers, paint brush, etc) usually tearing and ruining the decal. My

advice is not to use anything but the following as a decal bonder.

Using the decal bonder that comes

with the kit works fine however, I’ve also used the following.

The one on the bottom is Last Step

Decal Bonding Spray made by Super Cal unfortunately; this company no longer

makes it, so if you find a clear Polyurethane spray (like the one on top)

it will work. The obvious advantage in

using the large can is cost.

After printing the decal sheet I tape

the corners of the sheet down to a cardboard box using clear magic tape, (be

careful not to cover any designs). The box keeps me from handling the sheet

after spraying on the bonder. Apply the bonder spray using a couple of light

coats, (usually up/down and side to side) then set aside to dry for about an

hour. After drying I usually repeat the above steps and wait for them to dry

again. Then you can remove the sheet from the box and use the decals.

Sometimes I find that I don’t have

enough designs to fill up an entire sheet or perhaps I’ve got some designs for

clear paper and some for white paper.

Being a somewhat impatient person I don’t want to wait until I have

enough designs to fill an entire sheet so I’ll let you in on a trick that works

for me. I go ahead and print out the partial sheet of designs, I make sure what

designs I do have are clustered at the top of the sheet, (remember about

maximizing the design space on the sheet?). Once I have printed the designs I trim

off the designs square to the rest of the sheet, (I

haven’t sprayed them with

the bonder at this point)

Now I put the partial sheets of decal

paper with no designs someplace safe, (like back in the package or in a zip

lock bag). It’s important that you don’t spray the decal bonder on the unused

sheets or you won’t be able to reuse them.

The partial sheets with

designs can now be sprayed with bonder and used like normal.

Now let’s say that later I’ve got a

partial sheet of designs I want to print again, well rather than using a full

sheet I use the ruler on the design screen to determine if I have a partial

sheet large enough to print them on. Sending a partial sheet through the

printer by itself won’t work. You’ll need to print a calibration sheet.

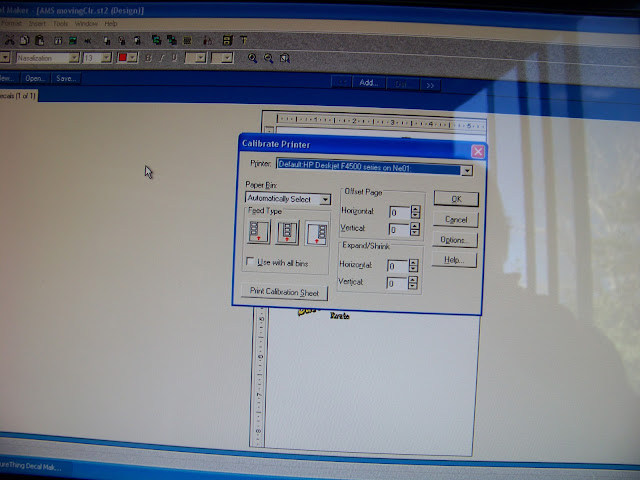

From the decal maker software, under

the File menu is the ‘Calibrate Printer’ selection. Select the paper bin

setting you wish to use and then click ‘Print Calibration Page’, (button on

lower left). This will print a page which shows you how the decal sheet is

oriented with respect to an 8 ½” x 11” sheet of paper. Ignore the text

information printed on the Calibration sheet; we’re only interested in the area

inside the lines. Now with this Calibration sheet you can tape your partial

decal sheet to the Calibration sheet being careful to align it inside the lines

on the sheet approximately where the designs will print, (remember not to cover

any designs with tape). Now you can send the combined sheets through the

printer. Separate the sheets, remove the tape, apply bonder and you’re good to

go!

I wish that in future such posting should go on.

ReplyDeletecustom stickers

dye cut stickers